Magnetic Strainer F-TIKAL DN150

Magnetic Strainer F-TIKAL DN150

[arwp ulr=”https://tikalfilter.com/wp-content/uploads/2024/08/Ftikal.usdz”]

154.968.000تومان

ارسال سریع

تمام نقاط کشور

پرداخت امن

درگاه پرداخت امن

مشاوره رایگان

جهت انتخاب محصول

گارانتی 5 ساله

بدون قید و شرط

Key Features of the F-TIKAL DN150 Magnetic strainer

Durable Body Construction: Made from ST52 steel with a hot-dip galvanized protective layer and triple-layer epoxy coating for enhanced resistance to corrosion and rust.

Flanged Connections: Enables easy installation and setup with standardized flanged fittings.

High Magnetic Strength: Equipped with 4 to 10 powerful magnetic rods, each 25 to 35 cm in length, for effective sediment separation.

Easy Maintenance: Features semi-automatic sediment separation, eliminating the need for part replacement.

Wide Temperature Range: Suitable for operation in temperatures from 1°C to 85°C.

Stainless Steel Strainer: Includes an L304 stainless steel strainer for superior durability and efficiency.

Standardized Design: Flanges designed to PN standards, capable of handling working pressure up to PN16.

Reduced Pressure Drop: Provides a 50% lower pressure drop compared to conventional Y-strainers.

Reinforced Body: Steel body with anti-corrosion static paint for long-lasting durability.

Drain and Air Vent Ports: Equipped with dedicated ports for draining and air venting to streamline maintenance.

Wide Range of Sizes: Available in sizes ranging from DN50 to DN300 to accommodate various industrial applications.

2-Year Warranty: Backed by an unconditional 2-year warranty for added peace of mind.

|

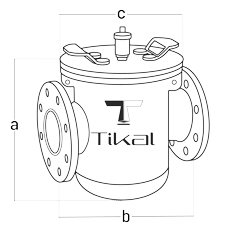

مدل |

c(mm) |

b(mm) |

a(mm) |

|---|---|---|---|

|

dn50 |

220 |

230 |

270 |

|

dn65 |

220 |

290 |

270 |

|

dn80 |

285 |

310 |

320 |

|

dn100 |

285 |

340 |

360 |

|

dn125 |

335 |

400 |

414 |

|

dn150 |

390 |

480 |

540 |

|

dn200 |

460 |

600 |

650 |

|

dn250 |

570 |

730 |

700 |

|

dn300 |

750 |

850 |

800 |

جدول سایز بندی F-TIKAL

Why Choose the FG-TIKAL magnetic strainer ?

The use of DN150 magnetic strainer in boiler rooms and heating or cooling circuits provides numerous benefits that enhance the performance and efficiency of industrial systems. These filters effectively separate suspended particles and deposits from the water flow, preventing their accumulation in sensitive equipment such as pumps, heat exchangers, and boilers.

This functionality results in an extended lifespan for equipment and a reduced need for frequent repairs, directly lowering maintenance and operational costs. Additionally, by optimizing water flow and reducing pressure drop, the system’s efficiency improves significantly, leading to substantial energy savings.

Reviews

Clear filtersThere are no reviews yet.