Showing all 21 results

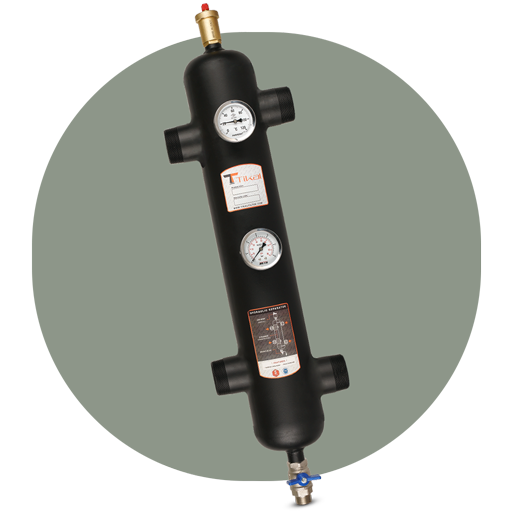

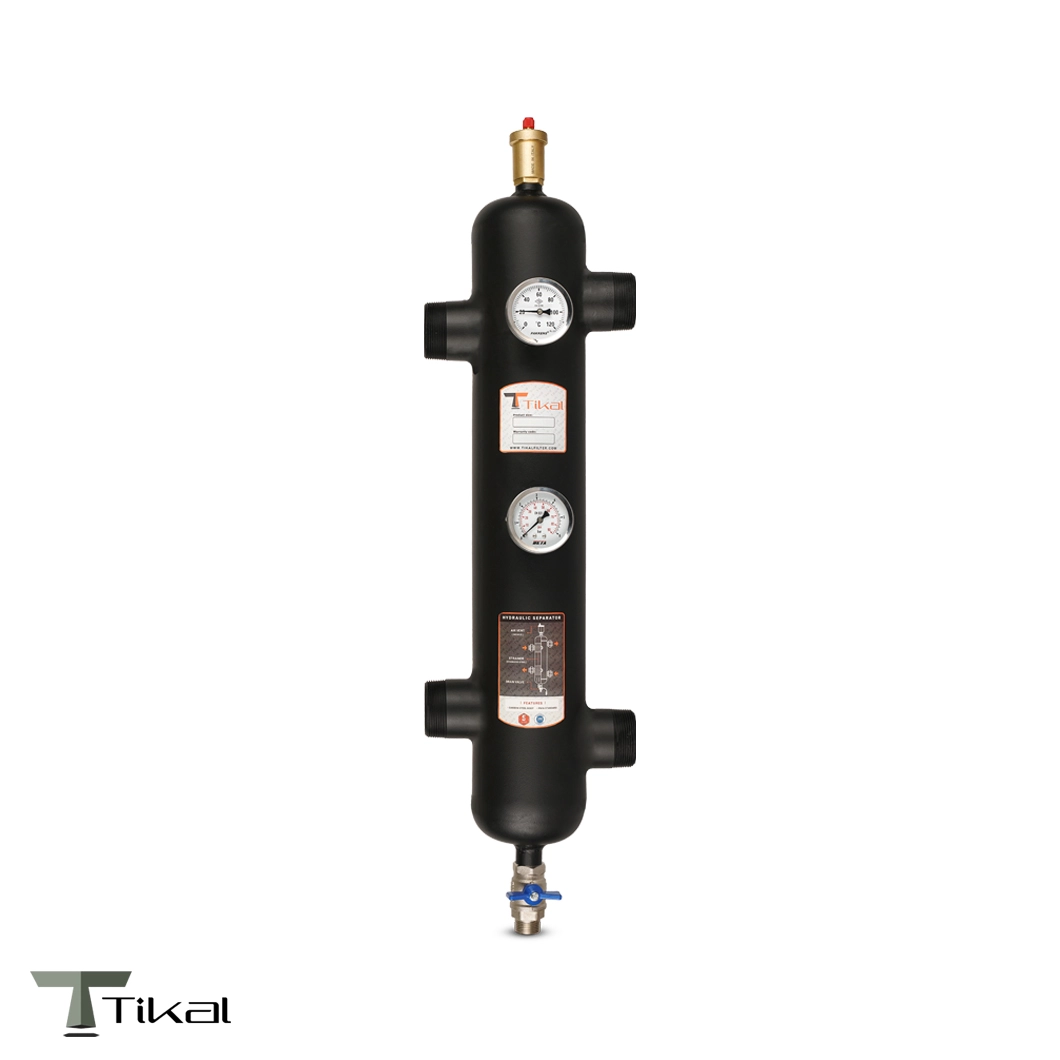

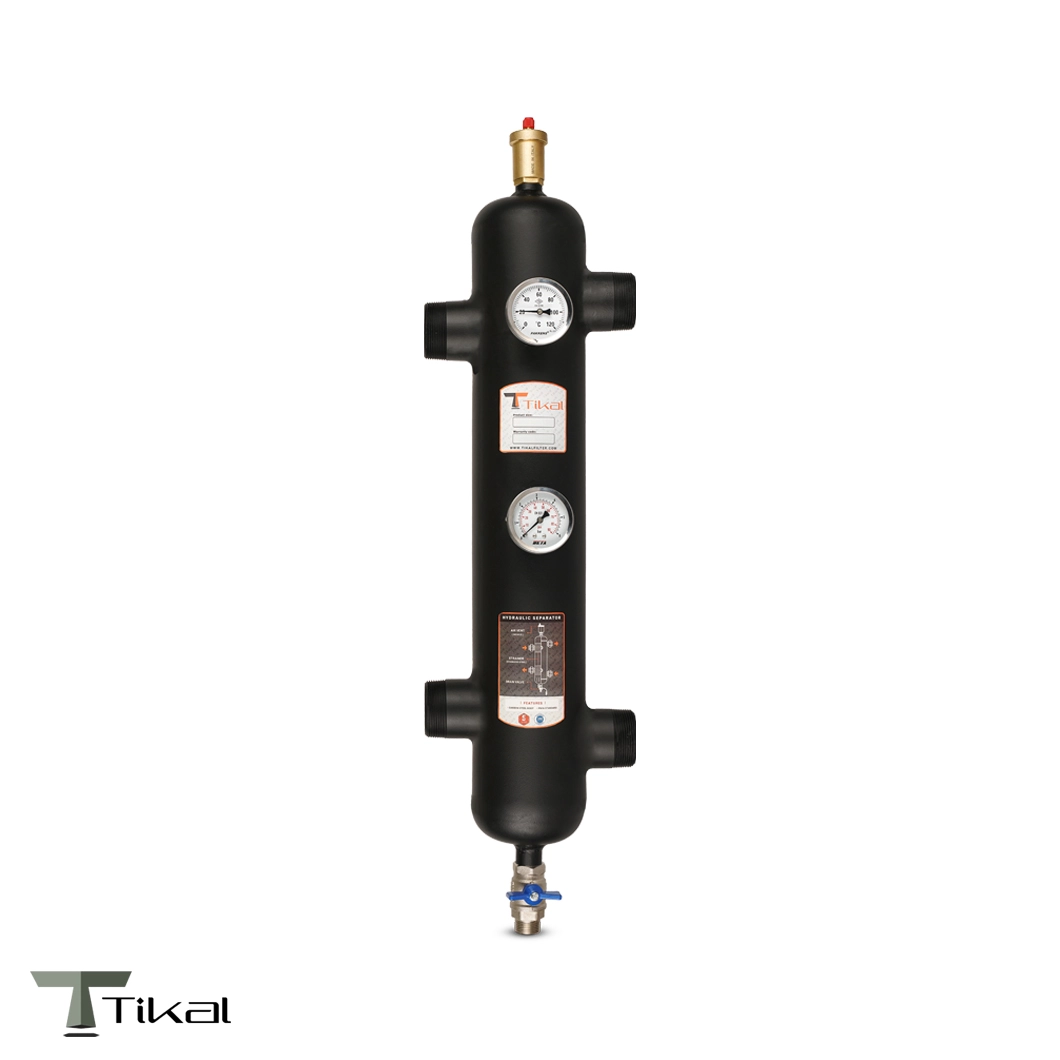

جداکننده هیدرونیکی + میله مغناطیسی 1.2-2 اینچ MH-Tikal

جداکننده هیدرونیکی + میله مغناطیسی 2 اینچ MH-Tikal

جداکننده هیدرونیکی + میله مغناطیسی 3 اینچ MH-Tikal

جداکننده هیدرونیکی + میله مغناطیسی 4 اینچ MH-Tikal

جداکننده هیدرونیکی + میله مغناطیسی 5 اینچ MH-Tikal

جداکننده هیدرونیکی + میله مغناطیسی 6 اینچ MH-Tikal

جداکننده هیدرونیکی + میله مغناطیسی 8 اینچ MH-Tikal

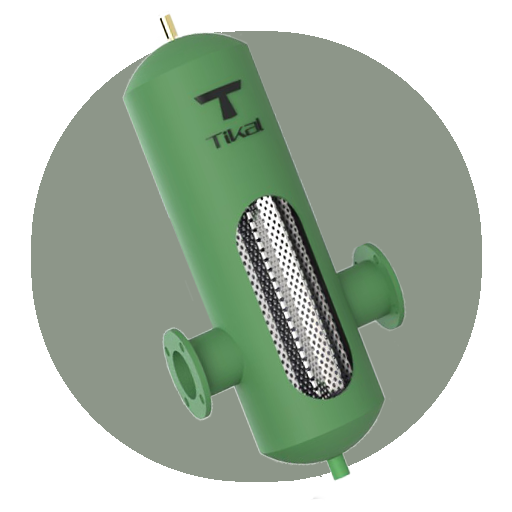

hydronic separator

The heating hydronic separator is one of the key components in dual-circuit heating systems, playing a significant role in enhancing the efficiency and performance of these systems. With the growing demand for efficient and optimized heating systems, the use of hydronic separator has gained attention as a vital tool in the design and operation of such systems. This article introduces the heating hydronic separator, explaining its functionality and applications.

?What is a Heating Hydronic Separator

A heating hydronic separator, also known as a hydronic separator, is a device used in dual-circuit heating systems to separate water flows between primary and secondary circuits. This equipment is employed to maintain mass and pressure balance, remove air and suspended particles, and store heat within heating systems. The hydronic separator helps reduce pressure loss, improve heat transfer, and thereby enhances the overall efficiency of the system.

Applications of a Heating Hydronic Separator

Mass and Pressure Balancing

The hydronic separator ensures that water flows uniformly and in balance across different circuits in the system, leading to increased system efficiency and reduced energy consumption.

Air and Particle Separation

A key function of the hydronic separator is to remove air and suspended particles from the water. This reduces sediment buildup and corrosion in pipes and equipment, thereby extending the system’s lifespan.

Heat Storage

The hydronic separator can act as a temporary reservoir for storing excess heat. This feature stabilizes system temperatures and enhances overall performance.

Pressure Drop Reduction

By using a hydronic separator, pressure drops in the system are minimized. This reduces the need for more powerful pumps, consequently lowering energy consumption.

Improved Heat Transfer

Through precise balancing of water flows and preventing negative interferences, the hydronic separator aids in optimizing heat transfer between different circuits.

The heating hydronic separator plays a critical role in enhancing the efficiency and lifespan of dual-circuit heating systems by balancing water flows, removing suspended particles and air, and minimizing pressure drops. Given these advantages, incorporating a hydronic separator in the design and operation of modern heating systems is a smart and efficient choice.

Definition and Functionality of Dual-Circuit Systems with H-Tikal

In today’s advanced world, dual-circuit heating systems are recognized as one of the most efficient and widely-used technologies for optimizing energy consumption and improving comfort in residential and industrial environments. These systems, thanks to their specialized design, possess the ability to balance and enhance efficiency. This article examines the definition, functionality, and advantages of dual-circuit systems.

How Dual-Circuit Systems Work

The operation of dual-circuit systems is designed to ensure maximum efficiency and performance in heating systems. The process involves several stages and functions, as detailed below:

Flow Separation

The primary and secondary circuits operate independently, but thermal flows are transferred between them using hydronic separators or sequential three-way valves. This separation reduces pressure loss and improves the system’s efficiency.

Mass and Pressure Balancing

By maintaining mass and pressure balance between circuits, dual-circuit systems prevent temperature and pressure fluctuations. This balance enhances the system’s overall performance and extends the lifespan of equipment.

Precise Temperature Control

With pumps and heat exchangers in each circuit, the system allows precise temperature adjustments in various parts of the system. Users can independently set the desired temperature for different sections of a building or industrial facility.

Energy Consumption Reduction

The separation of circuits and the use of optimized equipment reduce energy consumption in dual-circuit systems. Precise control of temperature and flow eliminates the need for continuous and full-capacity operation of pumps and boilers.

Flexibility and Scalability

Thanks to their modular design and the ability to separate circuits, dual-circuit systems offer high flexibility. This feature enables the expansion and increased capacity of the system without requiring significant structural changes.

Advantages of Using Hydronic Separators in Heating Systems

The use of hydronic separators in dual-circuit heating systems not only enhances system performance but also increases the efficiency and lifespan of equipment. By achieving mass and pressure balance, separating air and suspended particles, and storing excess heat, hydronic separators play a pivotal role in optimizing heating systems. This section provides a detailed review of the benefits of using hydronic separators in such systems.

Energy Consumption Reduction

Pressure balancing reduces the energy required for water movement within the circuits, ultimately lowering energy costs.

System Stability

The body of the hydronic separator is constructed from high-quality, durable materials. The use of stainless steel L304 in the strainer structure ensures high resistance to corrosion and rust.

How a Hydronic Separator Works in Modern Water-Based Systems

A hydronic separator is a key component in modern water-based heating systems, significantly contributing to improved efficiency and system performance. By managing and separating water flows, it plays a crucial role in maintaining mass and pressure balance, preventing temperature fluctuations, and extending the lifespan of equipment. This article outlines how a hydronic separator functions and explores the various modes of water circulation in these systems.

How a Hydronic Separator Works

In modern water-based heating systems, the hydronic separator operates as a specialized device that separates and manages water flows between primary and secondary circuits. This separation is carried out through several processes:

Flow Separation

The hydronic separator divides water flows into distinct circuits:

- The primary circuit includes the boiler and primary pumps.

- The secondary circuit involves secondary pumps and heat exchangers.

This separation ensures pressure balance and reduces temperature fluctuations within the system.

Water Entry into the Hydronic Separator

Hot water from the boiler or heat source enters the hydronic separator.

- This water may contain air and suspended particles, which require separation

Water Exit from the Hydronic Separator

Filtered water, free of air and suspended particles, is distributed to various circuits within the system.

- This purified water is then delivered to heat exchangers and other heating equipment.

Different Water Circulation Modes in Modern Water-Based Systems

Water circulation in modern water-based heating systems can occur in various modes, each with its specific characteristics and advantages.

Equal Flow Rate in Primary and Secondary Circuits

- In this mode, the water flow rate in the primary and secondary circuits is identical.

- This scenario is rare and typically does not occur in dual-circuit systems.

- The system is in perfect balance, experiencing minimal pressure loss.

Higher Flow Rate in the Primary Circuit Compared to the Secondary Circuit

- This mode occurs when the pumps in the secondary circuit are either turned off or operating at reduced capacity.

- Hot water from the primary circuit enters the hydronic separator, and only a portion of it is transferred to the secondary circuit.

- This mode results in increased temperatures in the primary circuit while reducing energy consumption.

Higher Flow Rate in the Secondary Circuit Compared to the Primary Circuit

- In this mode, the water flow rate in the secondary circuit exceeds that in the primary circuit.

- It occurs when there is a higher demand for heating in the secondary circuit.

- Hot water from the primary circuit enters the hydronic separator and is quickly directed to the secondary circuit, improving heating efficiency in different parts of the system.

Dimensions and Design of a Heating Hydronic Separator

Dimensions of a Heating Hydronic Separator

The dimensions of a hydronic separator vary based on the heating system’s capacity and specific requirements. Proper dimension selection depends on factors such as water flow rate, system volume, and application type. Below is a sample table outlining the dimensions of different hydronic separators:

| Model | Inlet/Outlet Diameter (inch) | Height (mm) | Body Diameter (mm) | Maximum Flow Rate (L/min) |

|---|---|---|---|---|

| H-Tikal 3.4 | 1 | 300 | 100 | 50 |

Selecting the correct dimensions ensures optimal system performance, balanced flow, and efficient operation.

Shape of the Hydronic Separator

The design of a hydronic separator is optimized to ensure efficient separation and management of water flows. The standard shape consists of a cylindrical body with multiple inlets and outlets strategically positioned to distribute water flows evenly across the system.

Key Design Features

- Cylindrical Body: Ensures uniform flow and minimizes pressure loss.

- Multiple Inlets and Outlets: Facilitates easy connection to primary and secondary circuits.

- Air Release and Drain Valves: Allows for the removal of air and suspended particles from the water.

Warranty Terms

The hydronic separator is backed by a 5-year warranty, covering all components and performance of the device. Warranty terms include:

- Proper usage in accordance with the provided instructions.

- No unauthorized repairs or modifications.

- Regular maintenance and servicing of the device.

After-Sales Services

We provide comprehensive after-sales services, including:

- Telephone and online support.

- Supply of spare parts.

- Technical consultation.

Our goal is to ensure complete customer satisfaction and optimal device performance.

FAQ

A heating hydronic separator is a device used in heating systems to separate and manage water flows across various circuits. It enhances the performance and lifespan of heating systems by reducing pressure and temperature fluctuations, removing air and suspended particles from the water, and maintaining mass and pressure balance.

Using heating hydronic separators offers numerous benefits, including:

- Improved system efficiency.

- Reduced energy consumption.

- Prevention of temperature and pressure fluctuations.

- Extended lifespan of heating equipment.

Reduced maintenance and repair needs.

Additionally, these devices improve water quality in the system by removing air and suspended particles.

Selecting the appropriate dimensions for a heating hydronic separator depends on factors such as water flow rate, system volume, and application type. To make the right choice, refer to standard hydronic separator dimension tables and select a model based on the system’s capacity and specific requirements.

In modern water-based systems, the hydronic separator operates by separating water flows between primary and secondary circuits. It improves system performance by:

- Removing air and suspended particles from the water.

- Maintaining mass and pressure balance.

- Reducing temperature fluctuations.

Hot water from the heat source enters the hydronic separator, where it is filtered and separated before being distributed to different system circuits

A hydronic separator differs from similar equipment, such as boilers and heat exchangers, in its function.

- Boilers and heat exchangers are used for heat generation and transfer.

- The hydronic separator, on the other hand, focuses on water flow management, mass and pressure balancing, and improving water quality within the system.

These differences make the hydronic separator a complementary and essential component for optimizing the performance of heating systems.